Klüber Screw Compressor Oils

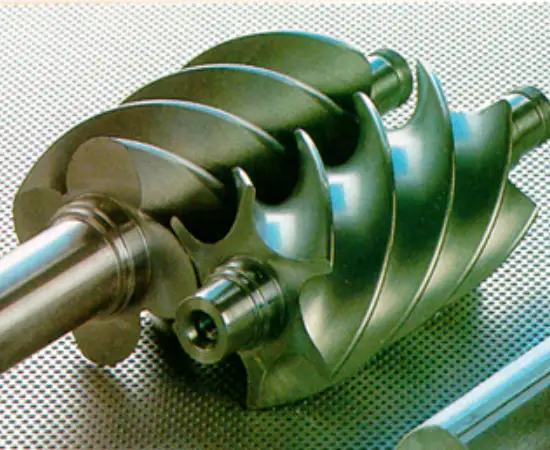

Klüber Lubrication is a world leader in specialty lubricants, offering advanced solutions for critical industrial applications. Their screw compressor oils are engineered to provide long service life, excellent wear protection, and outstanding thermal stability, ensuring compressors run efficiently with reduced downtime.

- Advanced industrial solutions

- Long service life

- Superior wear protection

In air compression, two issues are especially important: the availability of clean compressed air where it is needed, and economically reasonable air compression costs. Picture this: production is in full swing, everyone’s happy. But then, without warning, one of the compression cylinders breaks down. It just ceases to do what it’s there for: delivering compressed air. In no time, there will be cries on the shop floor: “Pressure’s down! The compressor’s gone!” This scenario illustrates that while compressed air is normally an in - conspicuous element of the production Process its absence is felt immediately: without it, nothing works. 5,000 operating hours in oil-injected screw-type compressors.

Leading Edge Lubrication Technology

Klüber Summit’s ongoing commitment to research and development keeps its compressor lubricants at the forefront of lubrication technology. We offer a wide range of semi-synthetic and synthetic compressor oils that deliver significant advantages over conventional mineral and synthetic oils, including:

- Extended oil change intervals

- Excellent evaporation stability with less oil carryover

- Reduced carbon residue formation

- Lower electricity consumption

- Superior oxidation stability

- High viscosity index

- Environmentally friendly performance

Klüber Summit PS 200

Klüber Summit PS oils have been especially designed for the lubrication of screw-type and reciprocating piston compressors. They are used for oil change intervals up to 5,000 operating hours in oil-injected screw-type compressors.

These oils can be used for compressors that were previously run with conventional mineral oils. They are neutral towards most elastomer seals used in air compressors, therefore leakage is not expected.

Klüber Summit PS oils are recommended for compressors which do not achieve the desired maintenance intervals with mineral oils and where fully synthetic oils would be uneconomical due to contamination risk or low yearly operating hours.

PS 100 can also be used for turbo compressors, while PS 300 and PS 400 are specially developed for reciprocating piston compressors.

These oils offer excellent oxidation stability due to the synthetic base oil content, minimising residues, extending oil change intervals, and increasing the service life of oil filters and separators. Special inhibitors keep compressors clean and ensure high efficiency.

Technical Specifications

| Appearance | Clear |

| Density (DIN 51757, 20 °C) | Approx. 0.88 g/cm³ |

| Kinematic viscosity (40 °C) | Approx. 68 mm²/s |

| Kinematic viscosity (100 °C) | Approx. 8.4 mm²/s |

| Viscosity index (DIN ISO 2909) | >= 90 |

| Flash point (DIN EN ISO 2592) | >= 230 °C |

| Pour point (DIN ISO 3016) | <= -27 °C |

Klüber Summit SH-46 Series

Klüber Summit SH oils are air compressor oils based on synthetic hydrocarbon and additives. They can be mixed with mineral oils and synthetic hydrocarbon oils, but not with Polyglycol oils.

They can also be used for compressors that were previously run with mineral oils. These oils are neutral towards most elastomer seals used in air compressors, therefore leakage is not expected.

Klüber Summit SH oils have been designed for the lubrication of highly loaded, oil-injected screw-type compressors with oil change intervals up to 10,000 operating hours. SH 32 is suitable for centrifugal compressors and SH 100 for reciprocating piston compressors.

They offer excellent oxidation stability, reduce oil vapor content, lower oil consumption, prevent valve gumming, and ensure clean compressed air.

Benefits for your application:

- Extended oil change intervals up to 10,000 hours

- Easy oil conversion due to seal compatibility

- Low evaporation, cleaner compressed air

- Longer service life of filters & separators

- Reduced oxidation residues and operating costs

- Improved energy efficiency

Technical Specifications for SH 46

| Appearance | Clear |

| Density (20 °C) | Approx. 0.85 g/cm³ |

| Kinematic viscosity (40 °C) | Approx. 46 mm²/s |

| Kinematic viscosity (100 °C) | Approx. 7.3 mm²/s |

| Viscosity index | >= 115 |

| Flash point | >= 240 °C |

| Pour point | <= -36 °C |

Technical Specifications for SH 68

.webp)

| Appearance | Clear |

| Density (20 °C) | Approx. 0.86 g/cm³ |

| Kinematic viscosity (40 °C) | Approx. 68 mm²/s |

| Kinematic viscosity (100 °C) | Approx. 9.8 mm²/s |

| Viscosity index | ≥ 115 |

| Flash point | ≥ 240 °C |

| Pour point | ≤ -36 °C |

Klüber Summit Varnasolv

Klüber Summit Varnasolv is a concentrated synthetic conditioner for cleaning screw compressors, hydraulic systems, gears, and oil circulation systems.

It dissolves varnish and carbon build-ups during operation and keeps them suspended in the oil, eliminating the need to dismantle the system for cleaning. After treatment, the oil with residues is fully drained and replaced with fresh oil.

Technical Specifications

| Appearance | Clear, Yellow |

| Density (20 °C) | Approx. 0.98 g/cm³ |

| Kinematic viscosity (40 °C) | Approx. 75 mm²/s |

| Flash point | >= 165 °C |

Klüber Summit Supra Coolant

Klüber Summit Supra Coolant oils are fully synthetic polyglycol-based compressor oils designed for up to 8,000 operating hours in oil-injected screw compressors.

Supra 32 is suitable for turbo compressors, and Supra 26 N offers oil life up to 40,000 hours with regular monitoring.

They are miscible with other polyglycol oils and the Klüber Summit Ultima series, but not with mineral or synthetic hydrocarbon oils.

Technical Specifications

| Appearance | Clear, Yellow |

| Density (20 °C) | Approx. 0.96 g/cm³ |

| Kinematic viscosity (40 °C) | Approx. 55 mm²/s |

| Kinematic viscosity (100 °C) | Approx. 9.5 mm²/s |

| Viscosity index | >= 145 |

| Flash point | >= 240 °C |

| Pour point | <= -36 °C |

Extended Oil Life, Reduced Costs & Higher Availability

Extend the oil change intervals for your compressor by using special, oxidation-resistant compressor oils made by Klüber Lubrication. Our products provide multiple advantages:

- Reduced maintenance costs otherwise spent for external or internal services

- Increased compressor availability

- Reduced spare parts costs for oil, oil filter and oil separator

- Less used oil disposal, making operations more eco-friendly

Not all compressor oils are the same. A high-quality product offers strong oxidation protection. The intense contact between the oil and oxygen at high compression temperatures directly impacts oil performance. Good oxidation resistance depends on both the base oil and the additives used.

The primary characteristic of poor oxidation resistance is a sharp rise in the neutralization number, which shortens oil life. Prolonged use can lead to sludge and residue formation in the compressor oil cycle. Such deposits cause wear, clog filters and separators, and reduce overall service life.

Reduce Worries and Maintenance Costs

Evaporated oil is not removed by the oil separator but entrained into the compressed air network. The oil’s tendency towards evaporation depends on its exact composition. Klüber Summit compressor oils are close-fractioned, which means they evaporate up to 20 times less than conventional compressor oils. And why should that interest you?

- Low oil consumption of the compressor

- Oil-free compressed air

- Longer activated carbon filter life

- Clean compressed air network, less residues and glueing, problem-free operation of pneumatic valves

Compared with conventional mineral oils, the synthetic oils made by Klüber Lubrication offer substantial benefits: they evaporate much less at normal discharge temperatures. Conventional oils contain highly volatile components. The resulting oil vapor is entrained with compressed air and cannot be separated by the oil separator because it is in gaseous state. This vapor puts additional strain on compressed air processing and, upon condensation, affects the entire compressed air network.

Considerably Less Evaporation with Synthetic Oils

Especially in applications where oil-free compressed air is vital, such as in the food-processing or pharmaceutical industry, the positive effects are clear:

- Low load on activated carbon filter and compressed air processing with longer service lives

- Higher reliability with less oil contained in compressed air

- Cleaner compressed air network

Our Products

- Semi Synthetic KLUBER PS200

- Fully Synthetic KLUBER SH46

- Fully Synthetic KLUBER SH68

- Polyglycol Synthetic KLUBER Supracoolant

- KLUBER Varansolv